As a cnc machine tool manufacturer, I understand the importance of sustainable practices in our industry. In this guide, I will discuss how manufacturers can adopt sustainable practices to minimize their environmental impact and contribute to a greener future.

The Role of CNC Machine Tool Manufacturers in Sustainability

CNC machine tool manufacturers play a crucial role in promoting sustainability by developing and producing machines that are energy-efficient and environmentally friendly. By incorporating advanced technologies and materials, these manufacturers can reduce energy consumption, waste generation, and carbon emissions throughout the lifecycle of their products.

Conprofe Ultrasonic: Leading the Way in Sustainable Manufacturing

One notable example of a CNC machine tool manufacturer committed to sustainable practices is Conprofe Ultrasonic. This company has implemented various initiatives to reduce its ecological footprint. They have optimized their manufacturing processes to minimize material waste and developed innovative recycling programs for used components.

In addition, Conprofe Ultrasonic has invested heavily in research and development to create cutting-edge machines that consume less energy without compromising performance. Their commitment to sustainability extends beyond production; they also prioritize eco-friendly packaging materials and promote responsible disposal methods for their products.

The Advantages of 5 Axis CNC Engraving Machines

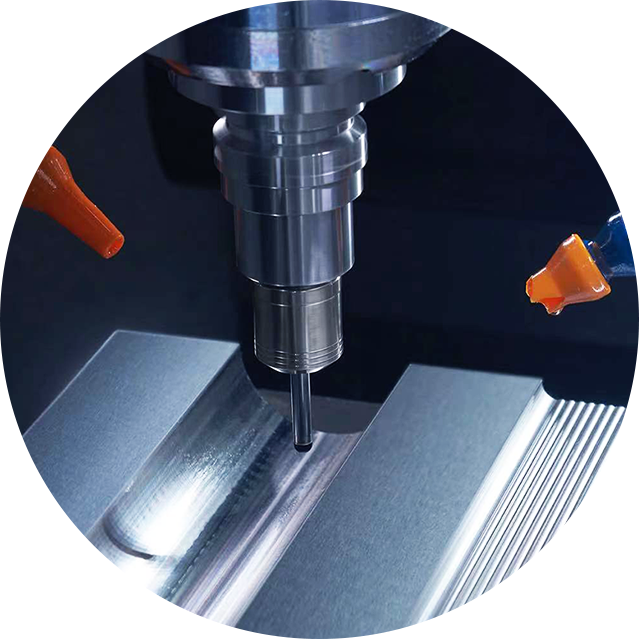

A significant advancement within the CNC machine industry is the introduction of 5 axis cnc engraving machines. These machines offer enhanced precision, versatility, and efficiency compared to traditional models. With multiple axes of movement, they can produce complex designs with minimal setup time.

Besides improving productivity, 5 axis CNC engraving machines also contribute towards sustainability efforts. Their advanced software allows for optimal material utilization by minimizing wastage during machining processes. Additionally, these machines often incorporate smart features such as automatic tool calibration and energy-saving modes, further reducing their environmental impact.

Conclusion

CNC machine tool manufacturers have a responsibility to prioritize sustainable practices in their operations. By investing in research and development, optimizing manufacturing processes, and producing energy-efficient machines like the 5 axis CNC engraving machines offered by Conprofe Ultrasonic, we can contribute to a greener future for our industry.